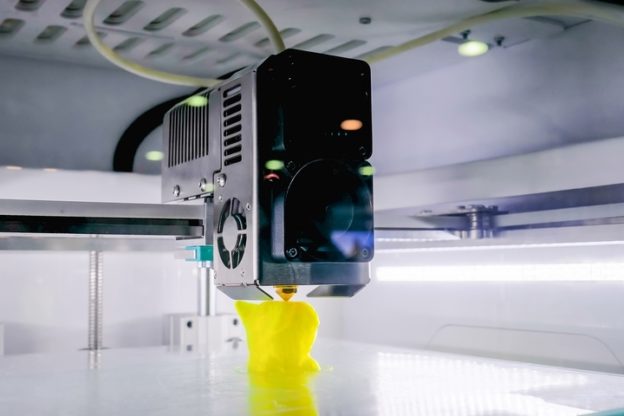

Sending a project to your 3D printer is as easy as first creating the perfect model image. It’s not always easy to get the right image for a workable printing job. Below are a few things to keep in mind when creating your model.

1- Not Accounting for Wall Thickness

Depending on the printer and material used, the wall thickness is an important consideration when creating the model to use. Planning your design with walls that are too thick or thin will present quality issues and jeopardize the results of the actual printing. Walls that are too thin will be impossible to print in many cases. Walls too thick can increase internal stress and cause materials failure when printed.

2- Using the Wrong Software

The software you choose to use to create the model for printing should be comfortable and give you the design capabilities you need for the products you want to make. Many brands of software available on the market. It’s best to give each a try before settling on one and investing a lot of money in the software you may not like after using a few times. For more information, www.argylematerials.com offers additional resources on their website.

3- Not Following Software Guidelines

Completing a 3D model doesn’t necessarily mean it’s ready for printing. Some details, such as wall thickness, have to be manually added with some software programs. Check the guidebook that comes with the software and find out as much as you can about going from a 3D model to 3D printing. You can also find tutorials online that help.

4- Using the Wrong File Resolution

A 3D printer needs a file resolution with a tolerance of about 0.01mm in size. Anything smaller will be too detailed for the printer to handle. Anything larger will provide rough results. Always set your resolution to the tolerance recommended by your printer. The tolerance of resolution is set at the time you save the file.

5- Not Understanding the Printing Technology

Gain an understanding of the basics of the technology with 3D printing before starting your project design. You need to understand what materials can tolerate particular design shapes and interworkings in order to get realistic and usable results. Your model needs to be a design that can go on to the printer and become your next product or part.

6- Ignoring the Material Guidelines

Not all materials will work for your specific design. Familiarize yourself with the capabilities of the materials you want to use and design accordingly. Learn from other creators in the techniques and materials they used to achieve design success.

Carefully create the model you will use to send to the 3D printer following the guidelines and recommendations for your particular type of printer.